DBHT Alcohol Recovery Concentration Tower

Description

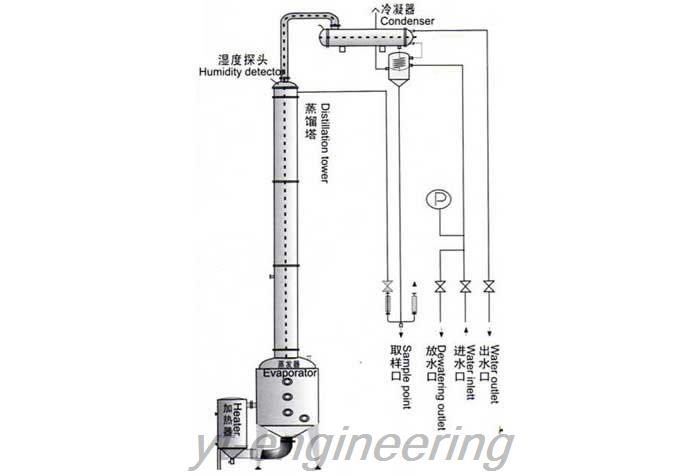

Alcohol recovery tower is made up of tower bottom, the tower, condenser, cooler, buffer tank and the high tank. This alcohol recovery concentrator is able to distill dilute alcohol from 30-50 degrees to 93-95 degrees.

Application

Alcohol recovery tower is applied to the dilute alcohol recovery of pharmaceutical, food, light industry and chemical industries.

Features

1.The material contact parts of alcohol recovery tower are made of stainless steels OCr18Ni9, which features good corrosion resistance, energy-saving, environmental protection, reducing production costs and improving efficiency.

2.Alcohol recovery concentrator adopts stainless steel corrugated packing in high efficiency.

Parameters of Alcohol Recovery Tower

| Model | DBHT200 | DBHT300 | DBHT400 | DBHT500 | DBHT600 | DBHT800 | |

| Tower Volume (l) | 640 | 1220 | 1450 | 2300 | 2500 | 3200 | |

| Height of Tower (mm) | 6000 | 7000 | 7000 | 7000 | 7500 | 7500 | |

| High Tank Capacity (L) | 300 | 400 | 650 | 800 | 1000 | 1500 | |

| Condensation Area (㎡) | 5 | 9 | 11 | 18 | 25 | 45 | |

| Cooling Area (㎡) | 1 | 1.5 | 2.2 | 4 | 6 | 8 | |

| Heat Transfer Area (㎡) | 3.0 | 6.0 | 6.5 | 17 | 20 | 32 | |

| Recycling Capacity (kg/h) | 26 to 35 | 64 to 80 | 120 to 150 | 200 to 232 | 240 to 320 | 380 to 450 | |

| Recycling Concentration (%) | 90 | ||||||

| Packing Form | Ceramic/stainless steel corrugated packing | ||||||

| Vessel Classification | First class | ||||||

| Weight of Equipment (kg) | 1100 | 1900 | 2300 | 3800 | 4500 | 6800 | |

| Overall Dimensions (L × W × H, mm) | 2300 × 700 × 7300 | 2400 × 800 × 7500 | 2500 × 1000 × 900 | 3000 × 1200 × 9000 | 3500 × 1400 × 10000 | 4200 × 1800 × 14000 | |

Process Flows

Lantoky has cooperated with the domestic universities and colleges for a long time. Meanwhile, we invite experienced professors and engineers to form expert group. Alcohol recovery tower machines have powerful research and development as well as innovation capacity. If you have any question about alcohol recovery concentrator machines, please feel free to contact us. Lantoky also warmly welcomes customers to visit the company.

English

English Русский

Русский 日本

日本