CQT Liquid-Liquid Continuous Extraction Tower

Description

CQT liquid-liquid continuous extraction tower is an improved machine which is on the base of single tank liquid mixing extraction, static multistage countercurrent extraction and emulsification extraction machine.

Application

CQT liquid-liquid continuous extraction tower is mainly used in chemical, traditional Chinese medicine and food industry. The following are the specific usage of extracting tower.

1.In chemical industry, extracting tower can be used to extract antibiotic and synthetic pigment from fermented liquid as well as remove phenols form wastewater.

2.In traditional Chinese medical industry, this liquid-liquid continuous extraction tower is able to extract alkaloids from acid extracts of medicinal plants, flavone from gingko and chemical composition from a variety of traditional Chinese medicines.

3.In food industry, extracting tower is used in milk protein, royal jelly, food additives and flavors extracting technology.

Features

1.Liquid-liquid continuous extraction tower integrates dynamic extracting and static extracting.

2. Heavy liquid and light liquid flow into the machine in convective form, which enables the droplets make good contact. This extracting tower is a more advanced machine at present and shares a good popularity among users.

Parameters of Liquid-Liquid Continuous Extraction Tower

| Diameter of Tower | Height of Tray | Overall Height | Flow | Electric Motor | Speed | Dynamic and Static Ring Spacing | Notes |

| 50 | 600 | ~1600 | 15 to 30 | 0.75 | 0 to 300 | 25 to 50 | Insulation kits |

| 75 | 800 | ~2200 | 25 to 50 | 1.1 | 0 to 300 | 25 to 50 | Insulation kits |

| 100 | 1100 | ~2800 | 80 to 110 | 1.5 | 0 to 300 | 25 to 50 | Insulation kits |

| 150 | 1500 | ~3200 | 120 to 160 | 2.2 | 0 to 250 | 25 to 50 | Insulation kits |

| 200 | 2000 | ~4600 | 200 to 260 | 3 | 0 to 200 | 25 to 50 | Insulation kits |

| 300 | 3000 | ~6400 | 350 to 450 | 4 | 0 to 160 | 25 to 50 | Insulation kits |

| 400 | 4000 | ~8000 | 600 to 1000 | 5.5 | 0 to 160 | 25 to 50 | Insulation kits |

| 500 | 5000 | ~10000 | 1000 to 2000 | 5.5 | 0 to 160 | 20 to 50 | Insulation kits |

| 600 | 6000 | ~12500 | 2000 to 3000 | 7.5 | 0 to 130 | 20 to 50 | Insulation kits |

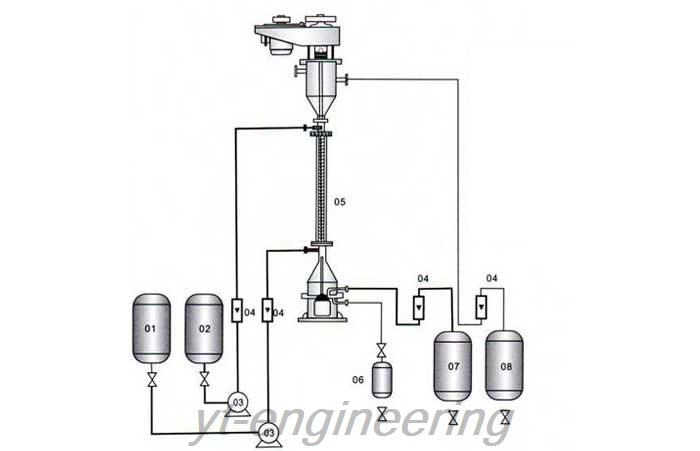

Process Flows

01 Solvent tank

02 Material tank

03-2 Material pump

04-4 Flow meter

05 Extraction column

06 Residual tank

07 Heavy liquid tank

08 Light liquid tank

Over the years, efforts are made to the development and production of extracting tower, granulating machine, drying machine and blending machine in China. Lantoky promises to provide customers with at least 10 years spare parts service, in order to avoid machine idleness due to the age of the equipment. Our products like liquid-liquid continuous extraction towers have been exported to America, Britain, Germany, Cyprus, Turkey, Greece, Ukraine, Malaysia, India, Vietnam, Thailand, Bangladesh, Singapore, Taiwan, Nigeria and Mexico.

English

English Русский

Русский 日本

日本